Consecutive Purchase of MPT's Pin Milling Production Line Shows Its High-Quality Spice Powder Grinding

Cyclone Separator and Dust Collector – No Powder Is Wasted

German Style Spice to Powder Milling & Grinding Turnkey Project From MPT

Consecutive Purchase of MPT's Pin Milling Production Line Shows Its High-Quality Spice Powder Grinding

Mill Powder Tech (MPT) has been a grinding and mixing machinery manufacturer from Taiwan for 70 years, and their client is a leading seasoning powder supplier. Hot pepper, black pepper, white pepper and cinnamon are the spices mainly sold by the client to Europe and Japan. As soon as you walk into their plant, among all the production lines from countries such as Taiwan, Japan, Europe and China, you can see three sets of turnkey projects from MPT. At ALLPACK Indonesia tradeshow, twenty years later, the client decided to order two extra production lines from MPT for their new factory. Why MPT? For the last 20 years, none of the machines from MPT needed any repairs, even during busy seasons when they required the machines to operate 24 hours a day.

Powder ginder PG-10 and PG-5. Application: foodstuff, chemical, coconut shell, chinese herb, pharmacy, curry powder, fish bone powder, coating, mineral stone...etc.

A lifespan three times longer, quality powder delivery, malfunction-free, high production, low labor cost, simple installation, and easy maintenance are what the client experienced. They never needed MPT to install the production line - that's how uncomplicated it is. For spices that are dry, crispy and contain less than 15% oil, PM6 is perfect. Actually, sugar is the major grinding product for most of buyers. MPT's pin mill turnkey project has been maximizing its production capacity and providing evenly sheared powders, which permits the Indonesian client to sell high-quality seasoning powders globally.

Grains, and Foodstuff Grinding System

German Style Spice to Powder Milling & Grinding Turnkey Project From MPT

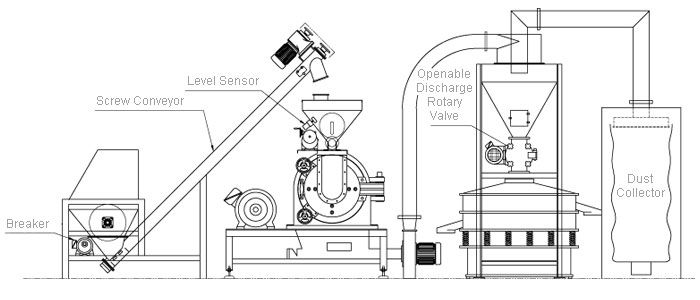

As a spice supplier, two factors necessary in order to provide high-quality spice powder are: to ensure the scent of spice is perfectly preserved, as well as to ensure each spice is evenly ground. For the last 70 years, beginning with Japanese style, to today's German milling system, MPT's milling and grinding equipment has avoided the heat effect on powder. Their client's spice milling turnkey project consists of feeding hopper, belt conveyor, hammer mill, pin mill, cyclone separator, dust collector and discharge rotary valve. The design, which separates the motor from the bearing and belt, along with hammer mill and pin mill's heat dispersion from rotor's rotation, means that powder's standard is elevated.

PM6, the spice grinding and milling production line, is designed for mass production without thermal influence.

We all now that overheated powder milling equipment can result in a change in the spice's flavor, scent preservation, and machinery malfunctions, along with shortened lifespan (70% of usage of machine is recommended), by allowing each component to operate independently, the machine's lifespan is prolonged. PM6, the spice grinding and milling production line, is designed for mass production without thermal influence.

Cyclone Separator and Dust Collector - No Powder Is Wasted

The powder handling processing line can also be used for various products, ranging from cinnamon, turmeric, black pepper, white pepper, herbs, etc.

When you insert 100 kg of spices into a grinder turnkey project, the output is also 100 kg. Nothing is wasted. Cyclone separator plays a role in directing where the powder gets collected. For new plant expansion, the cyclone separator is tailored for hygienic reasons. After multiple of shearing and grinding cycles, powder that can't pass through the filter mesh will get collected by the cyclone separator. Powder that does pass through would be the product that is ready for sale. The hammer mill and pin mill are responsible for the grinding processes, and the dust collector ensures nothing is wasted.

At the new plant, the PM6 production line used to mill hot pepper, white pepper, black pepper and cinnamon, is a combination of feeding hopper, belt conveyor, hammer mill, pin mill, cyclone separator, dust collector and discharge rotary valve. It is a heavy duty 50 HP milling system that is suitable for mass production, with150-200kg per hour and 20mesh ~ 150mesh fineness.

Cyclone separator plays a role in directing where the powder gets collected.

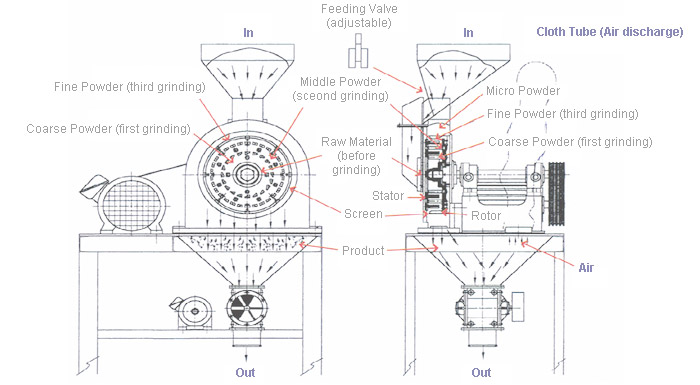

Pin Type Rotor Milling Machine for Your Spices

The Indonesian client chose a pin type milling machine to pulverize their spices. Stud type, pin type, and knife type rotors are optional for grinding raw spices into powders. Choosing a rotator gives you different results from grinding after going through three shearing and grinding procedures, adjusting filter mesh and changing knife size enhances the powder fineness in the end. Various kinds of spice milling can be done by switching washable knife and filter mesh, although single machine for one kind of spice is recommended, unless ozone treatment is applied.

| Stud Type Rotor | Stud Type Stator | Screen Ring | Application |

|---|---|---|---|

|  |  | Brittle materials: achieves exceptionally high grinding fineness at low specific energy consumption. |

| Pin Type Rotor | Pin Type Stator | Screen Ring | Application |

|  |  | Grains, Beans, Seasonings, etc. (e.g. Rice, Green Beans, Sugar, Salt). |

| Knife Type Rotor | Knife Type Liners | Screen Ring | Application |

|  |  | High Fiber & Heat Sensitive Raw Materials. (e.g. Chinese Herbs). |

Pin Mill Particle Size Distribution Report

Particle size distribution report paper is delivered with the milling machinery procurement, which proves filter mesh's efficiency and expectation of powder fineness is achieved. Generally, MP6 is a set of milling and grinding equipment with adjustable production amount and cutting size. If PM6 operated 24 hours a day, the production capacity would be 24 tons for sugar, 12 tons for rice, and 6 tons for seasoning spices.

| Model | PM-6 |

|---|---|

| Application | Foodstuff, Chemical Grade |

| Horse Power | 30~40 |

| RPM | 2800 |

| Capacity (kg/hr) | 300~900 |

| Dimension (m/m) | 1700*100*2400 |

| Fineness | 20~150 Mesh |

Milling & Grinding System for Soft to Medium-Hard, Hard Products

To cut bigger objects such as ginger, hot pepper, herbs or sugar, TM series cutting equipment is available. It has no filter mesh, therefore, alternate knife sizes is how you can cut with desired size. Pin mill (PM) grinding equipment suits dry and crispy foods that contains less than 15% oil, including coffee, sugar, beans, spices, flour, rice, etc. For oily or sticky products that contain over 15% oil, such as sesame and peanuts, PMM series grinding machine is available. For extra fine powder milling, APM grinding equipment is available.

PM standard pin mill suitable for grinding crystal and brittle materials. The output fineness can be changed by replacement of the filtering-screen and adjustment of the rotor speed.

PMT Low Maintenance Grinding and Milling Turnkey Project

PM6 is a powder milling turnkey project that has been around for so long that its design has been modified to include simple installation and easy maintenance over the course of time. Rotor is the only part that needs to be obtained from PMT, since all the holes are fixed, and so buying it somewhere else can be risky. Other than that, ordinary maintenance, such as changing bearing oil or switching air discharge cloth and filter screen, can simply be done by the client. In addition, having all the washable parts makes cleaning easy. Overloaded machine shuts down with its auto protection, and the user can simply unload everything and restart the machine.

A spice grinding and milling turnkey system with a lifespan three times longer, quality powder delivery, malfunction-free, high production, low labor cost, simple installation, and easy maintenance.

Grinding and Milling Equipment Customer Service from PMT

client testing their purchased spice grinding and milling production line

We have many clients that we haven't heard from for 20 years, because their machines never have major issues. The goal of our business is to provide good service to retain happy relationships., said a manager of PMT. In order to provide total solutions, if you are new to finding suitable grinding equipment, there is information you need to provide before receiving constructive suggestions, including the food that you wish to mill, the plant size and location, production capacity, and powder fineness requirements. Sometimes a buyer would send a sample product for MPT to grind.

The progress report is given prior to machine assembly, onsite and offsite lab testing and electricity examination videos are provided. Communication is always there thoughout the whole process. Operation training and the machine manual are delivered to ensure user's proper use of the machine.

ARTICLE SECTIONS

- Consecutive Purchase of MPT's Pin Milling Production Line Shows Its High-Quality Spice Powder Grinding

- Innovative Turbo Mill Creates New Market for a Japanese Company; Mill Powder Tech

- Turbo Mill That Handles Large Amounts, Hard to Cut Materials - Mill Powder Tech's Powder Handling Equipment Line Sold to Italy

- Mill Powder Tech Ginger Handling Line Delivers FDA Approval Ginger Powder

- Mill Powder Tech Coffee Bean Turnkey Solution Performs 100% Blending to Meet Cofi-Com Requirements

- Nestlé 3-In-1 Coffee Ribbon Mixer Turnkey Project Supplier From Taiwan

- Soy Milk Powder Equipment for a Leading Company in Hong Kong

- MPT Carrageen Powder Processing Equipment in Spain

- Pin Mill Supply in Taiwan – 70 Years. 70 Countries

- MPT Engineered Impact Classifier Mill For A Baking Powder Company In Japan

- Rice Powder Handling Processing Equipment in Canada

- ACI Limited and Square Group impact mill reliable supplier – MPT from Taiwan

- New! Micron Cyclone Mill Grinding System

- 70 Years. 70 Countries Powder Processing Equipment Supply - MPT

- Contact Now! Powder Mill Expert – Mill Powder Tech

- Send Inquiry Now! Powder Handling Expert – Mill Powder Tech

- MILL POWDER TECH(MPT) Privacy Policy

Milling and Grinding

Search related products

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Ready-eSupport

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Share