Pin Mill

Pin Milling Machine

Over 70 Years Powder Milling and Grinding Processing Equipment and Turnkey Project Manufacturer | Mill Powder Tech

Pin Mill (PM Series)

Pin Mill is suitable to grind crystal and brittle materials. The output fineness can be changed by replacement of the filtering-screen and adjustment of the rotor speed. With a wild range of applications to a variety of products, and the features of optional grind disc replacement for proper materials. Especially, this machine is easy to clean (water rinse) and do maintenance.

- Processes a wide range of raw materials. Durable, low-waste design.

- Easy to operate, saves time & power, highly efficient.

- Durable components are easy to replace & clean.

- Fineness: 20~150Mesh. (data is for reference only & may vary according to raw material)

Features

Ideal for pulverizing any materials (except highly oily or sticky ones). Due to the variety and interchangeability of internal components, this equipment has wide production adaptability, ranging from granular material to super-fine particles. Turnkey system is designed to prevent contamination of materials, increase efficiency, lower manpower requirements and maintain material quality.

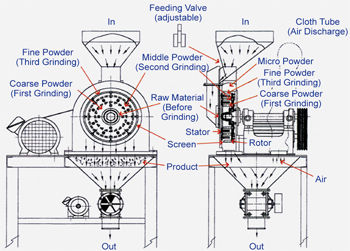

PRINCIPLE

Raw material is fed into the grinding chamber from the feeding hopper.

The first grinding is a shearing force created by the cutting impact of the inner rotor and stator.

After filtrating, any remaining coarser powder will be ground in the third grinding until it passes through the screen mesh.

The finished product is discharged from the rotary valve.

| ►PM-1 Compact Milling System | ►PM-3-C For Cosmetics | ►PM-3 For Foodstuffs |

|---|---|---|

|  |  |

| Stud Type Rotor | Stud Type Stator | Screen Ring | Application |

|---|---|---|---|

|  |  | Brittle materials: achieves exceptionally high grinding fineness at low specific energy consumption. |

| Pin Type Rotor | Pin Type Stator | Screen Ring | Application |

|  |  | Grains, Beans, Seasonings, etc. (e.g. Rice, Green Beans, Sugar, Salt). |

| Knife Type Rotor | Knife Type Liners | Screen Ring | Application |

|  |  | High Fiber & Heat Sensitive Raw Materials. (e.g. Chinese Herbs). |

Specification

| Application | Model | Power (HP) | RPM | Capacity (KG/HR) | Dimensions (L*W*H mm) | Fineness (Mesh) |

|---|---|---|---|---|---|---|

| GMP(Standard) | PM-3-A | 5~7 1/2 | 5000~7500 | 100~200 | 1000*600*1400 | 100~250 |

| GMP(Standard) | PM-4-A | 7 1/2~10 | 4500~6500 | 200~300 | 1100*700*1500 | 100~250 |

| Foodstuff & Chemical Grade | PM-1 | 2 | 3500 | 20~50 | 500*560*1300 | 20~150 |

| Foodstuff & Chemical Grade | PM-3 | 5~7 1/2 | 3500 | 80~250 | 1100*700*1550 | 20~150 |

| Foodstuff & Chemical Grade | PM-4 | 7 1/2~10 | 3000 | 100~300 | 1200*800*1750 | 20~150 |

| Foodstuff & Chemical Grade | PM-5 | 15~20 | 2900 | 150~500 | 1500*900*2200 | 20~150 |

| Foodstuff & Chemical Grade | PM-6 | 30~40 | 2800 | 300~900 | 1700*1000*2400 | 20~150 |

| Foodstuff & Chemical Grade | PM-7 | 50~60 | 2700 | 500~2000 | 1900*1300*2900 | 20~150 |

| Cosmetics Grade | PM-3-C | 7 1/2 | 3500 | 200~300 | 1000*860*1200 | 100~200 |

| Height from floor to outlet: 450 mm | ||||||

Capacity:

According to different characteristics of materials and equipment, the data would be changed.

Contact Mill Powder Tech Now!

ARTICLE SECTIONS

- Consecutive Purchase of MPT's Pin Milling Production Line Shows Its High-Quality Spice Powder Grinding

- Innovative Turbo Mill Creates New Market for a Japanese Company; Mill Powder Tech

- Turbo Mill That Handles Large Amounts, Hard to Cut Materials - Mill Powder Tech's Powder Handling Equipment Line Sold to Italy

- Mill Powder Tech Ginger Handling Line Delivers FDA Approval Ginger Powder

- Mill Powder Tech Coffee Bean Turnkey Solution Performs 100% Blending to Meet Cofi-Com Requirements

- Nestlé 3-In-1 Coffee Ribbon Mixer Turnkey Project Supplier From Taiwan

- Soy Milk Powder Equipment for a Leading Company in Hong Kong

- MPT Carrageen Powder Processing Equipment in Spain

- Pin Mill Supply in Taiwan – 70 Years. 70 Countries

- MPT Engineered Impact Classifier Mill For A Baking Powder Company In Japan

- Rice Powder Handling Processing Equipment in Canada

- ACI Limited and Square Group impact mill reliable supplier – MPT from Taiwan

- New! Micron Cyclone Mill Grinding System

- 70 Years. 70 Countries Powder Processing Equipment Supply - MPT

- Contact Now! Powder Mill Expert – Mill Powder Tech

- Send Inquiry Now! Powder Handling Expert – Mill Powder Tech

- MILL POWDER TECH(MPT) Privacy Policy

Milling and Grinding

Search related products

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Ready-eSupport

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Share