New! Micron Cyclone Mill Grinding System

Cyclone Mill - No Contamination. High Speed

Tea Leaf Processing Methods For Most Common Types Of Tea

Patented. cyclone mill grinding system. cyclone mill designed by Mill Powder Tech

The latest breakthrough to the conventional Pulverizer, and the best choice for micron grade grinding.

The grinding method of conventional grinders utilizes collision, cutting, and friction to accomplish the goal of powder refinement, typically such method produces from impact surface that contaminates the out-put material. When required particle fineness is in high micron, the contamination becomes worse. On the other hand, a capable JET MILL delivers refined powder without contamination, however it presents the problem of high energy consumption and inefficiency out-put performance. Thus, Mill Powder Techs combined the advantages of the two grinding methods, without the problematic impurity issues, and creates Cyclone Mill.

Scope of applications

Green tea powder

- Foodstuff:

- Green tea, black tea, sencha, barley tea, eucommia tea, refined rice, black bean, barley, dried shiitake, chitin, fish cartilage, Chinese herbal medicines, ganoderma lucidum, pearl, grains, burdock, mustard, clove, fennel, coriander, ginger, noni fruit, garlic, cinnamon, nutmeg, wild pepper, and so on.

- Industrial application materials:

- Calcium carbonate, silicon carbide, bamboo charcoal, black lead, bincho charcoal, coal, hydrated lime, iron oxide, coke, tourmaline, magnesium hydroxide, etc., as well as electronic materials, pharmaceutical raw materials, and cosmetic ingredients.

Grinding principle instruction

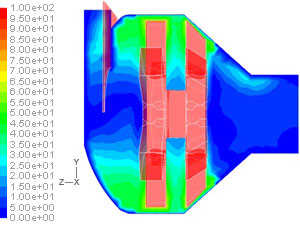

Speed distribution diagram

- Structure and grinding principle

- Combing effects of three grinding principles:

The mechanical grinding of fan blades, the air-flux collision effects between particles, and centrifugal force grading that makes CYCLONE MILL a new industrial innovation.- At first stage, the primary blade crush larger pieces of material mechanically; crushed particles then move towards a second blade to be pulverized again.

- During second stage, coarse powder carried by the high-speed air-flux circulating the first and second blades among particle body. Therefore, greatly reduced the friction created by particles hitting the blades. A large amount of air flow intake-exhaust exchange also reduced the particle temperature within the grinding process.

- Finally, by utilizing centrifugal force which equals the square ratio of rotational speed in the secondary blade, the air speed differential crates airflow grading. After ultrafine particles are being separated, powder then extracted by the negative pressure from the blower fan into storage bin.

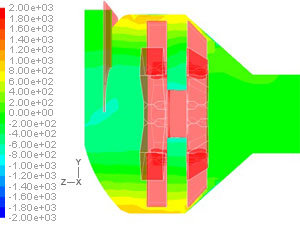

Pressure distribution diagram

- Six major features:

- CM pulverizer design that permits airflow grading capability; precision particle size distribution.

- Metallic debris from contact surface wear and foreign objects contamination are being limited by CM's innovated mechanically design.

- Open lid design of the grinding chamber makes maintenance easy.

- Applicable in both hard and soft materials.

- Grinding process reduces heat generation; materials do not degrade easily.

- High performance stats and minimal operation cost.

| Model | 250S | 400S | 600S |

|---|---|---|---|

| Host machine horsepower (HP) | 7 1/2 ~ 10 | 25 ~ 30 | 50 ~ 75 |

| Host machine rotational speed (RPM) | 6500 ~ | 5000 ~ | 3500 ~ |

| Fan motor horsepower | 5 ~ 7 1/2 | 10 ~ 15 | 30 ~ 40 |

| Grinding grade (um) | 5 ~ 150 | 5 ~ 150 | 5 ~ 150 |

| Handibg capacity (kg/hr) | 5 ~ 20 | 10 ~ 100 | 100 ~ 400 |

| Host machine weight (kg) | 220 | 820 | 1600 |

| Host machine dimensions (mm.) | 900*900*800 | 1560*1400*1350 | 2200*1900*1600 |

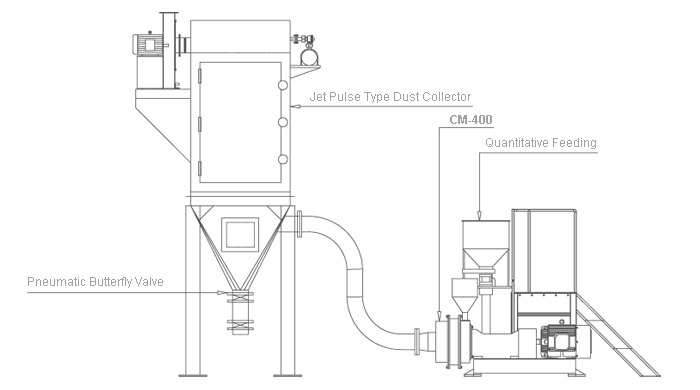

Cyclone mill grinding system

![]() 70 Years. 70 Countries Powder Processing Equipment Supply - MPT

70 Years. 70 Countries Powder Processing Equipment Supply - MPT

![]() ACI Limited and Square Group impact mill reliable supplier – MPT from Taiwan

ACI Limited and Square Group impact mill reliable supplier – MPT from Taiwan

ARTICLE SECTIONS

- Consecutive Purchase of MPT's Pin Milling Production Line Shows Its High-Quality Spice Powder Grinding

- Innovative Turbo Mill Creates New Market for a Japanese Company; Mill Powder Tech

- Turbo Mill That Handles Large Amounts, Hard to Cut Materials - Mill Powder Tech's Powder Handling Equipment Line Sold to Italy

- Mill Powder Tech Ginger Handling Line Delivers FDA Approval Ginger Powder

- Mill Powder Tech Coffee Bean Turnkey Solution Performs 100% Blending to Meet Cofi-Com Requirements

- Nestlé 3-In-1 Coffee Ribbon Mixer Turnkey Project Supplier From Taiwan

- Soy Milk Powder Equipment for a Leading Company in Hong Kong

- MPT Carrageen Powder Processing Equipment in Spain

- Pin Mill Supply in Taiwan – 70 Years. 70 Countries

- MPT Engineered Impact Classifier Mill For A Baking Powder Company In Japan

- Rice Powder Handling Processing Equipment in Canada

- ACI Limited and Square Group impact mill reliable supplier – MPT from Taiwan

- New! Micron Cyclone Mill Grinding System

- 70 Years. 70 Countries Powder Processing Equipment Supply - MPT

- Contact Now! Powder Mill Expert – Mill Powder Tech

- Send Inquiry Now! Powder Handling Expert – Mill Powder Tech

- MILL POWDER TECH(MPT) Privacy Policy

Milling and Grinding

Search related products

SEND YOUR INQUIRY

Looking for more information? You can fill out the Inquiry Form to tell us your needs or questions, we will respond soon!

Ready-eSupport

For LIVE HELP... just click "Live Help Desk", our specialists will be with you in air shortly.

Share